TQG Precision Planetary Gearboxes are Applied in Industrial Robotic Automation

Today we will share the application of low backlash inline planetary gearboxes and right angle planetary gearboxes used in robotic flight forming machines, which features of 8 axis robot production capacity.

Let us call our customer as A. One day in March, we got the inquiry from A, and he is from a robotics manufacturing company and wanted to purchase our gearbox to test out on their machines.

They use Beckoff servo motors on their machines and before they email us with the following detailed models, they have already reviewed our website and checked the related catalog pages of planetary gear box.

PFR080-10-S3-P2/Beckhoff AM8031

PAB090- 10-S3-P2/Beckhoff AM8031

PAR042-3-S3-P2/Beckhoff AS2023

PAR142-14-S2-P2/Beckhoff AM8062

PAR180-4-S3-P2/Beckhoff AM8072

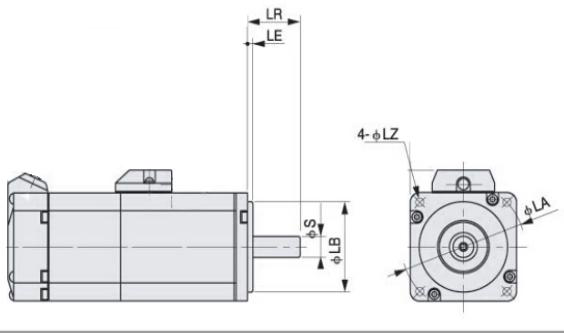

As a professional china planetary gearbox manufacturer, we firstly check all of our customers’ servo motor through the official website of Beckoff. Through the drawings of above servo motors, we got the motor input sizes and evaluate all the possibility for Beckoff motor to adapt our servo gearbox. During our correspondence, we found A wrote S3 in our model, then we confirmed with him and know he indeed needs the hollow output gearboxes. After several correspondences, he finally decided the following models and the quantity.

PAR090-10-S3-P2//Input size 14-60-75-M5(Φ6) Beckhoff AM8031

PAB090-10-S3-P2//Input size 14-60-75-M5(Φ6) Beckhoff AM8031

PAR142-14-S2-P2//Inputsize 32-130-165-M10(Φ11) Beckhoff AM8062

PAR180-4-S3-P2//Inputsize 38-180-215-M12(Φ13.5) Beckhoff AM8072

After that, we issued gearbox production drawings for their confirmation. Regretfully, we didn’t get their prompt feedback. Later we called A, and knew that he and his boss are in the Germany and will reply me soon. I asked whether they were in the Hannover Mess, and they were excited to tell me “yes”. I felt very happy and told them, we would also attend this exhibition. Hope we can meet. They replied “of course ” and they will visit our booth. Before the exhibition, the order had been placed and arranged to produce. You know that all the input sizes of Beckoff motors are non-standard. Not all the manufacture can customize the gearbox according to the motors. Yes, we can and finally meet A’s requirement. And our customer A also was appreciated our effort to confirm with them again and again about the model selection and drawing confirmation.

As the meeting with A and his CEO, trust between us are deepened. After finished the first order and they tested our precision gearboxes very well on their machines, A again placed the repeated order to us. Thanks for your trust and approval. I believe we will have more deeper cooperation in future and grow up together towards bright tomorrow.