NRV Worm Gear Reducer

Overview of NRV Worm Gearbox

- Fast heat dissipation

- Superior performance

- Smooth transmission

- Good sealing

- Low noise

- Small volume

- Maintenance-free

Descriptions of NRV Worm Gearbox

The TQG NRV worm gearbox adopts the “square box” structure with high-quality aluminum alloy casting box, which is beautiful in appearance, small in size, fast in heat dissipation, and flexible in installation. The whole machine adopts high-quality bearing transmission parts and seals to ensure durability and no leakage. What’s more, the worm gear pair adopt precision machining and precision meshing detection to ensure the balance of the machine transmission, low temperature-rising, low noise, high efficiency and long service life. Besides, The input and output parts of the NRV worm gearbox adopt precision finishing and the whole machine is rust-free and high-grade. The CVT is equipped with a worm gear reducer to adjust the output speed in the load and achieve stepless variable speed output. The manufacturing standard of NRV worm gearbox are based on the national standard GBl0085-88 cylindrical worm to ensure the superior performance.

Advantages of NRV Worm Gearbox

- Quick stop function

For a general gear reducer, it takes 5 to 10 seconds for the stop time, but for the NRV series, the stop state could be reachede with only 2 to 5 seconds.

- High safety

The NRV worm gearbox adopts a different way compared with the traditional one that it doesn’t need the sprocket and pulley. What’s more, transmission structure is not exposed so that injuries of operator could be reduced.

- Good protection

Grade IP55 is adopted which has good isolation for dust and moisture.

- Excellent thermal conductivity

The NRV worm gear is equipped with the cooling ribs, so that the body has excellent thermal conductivity and low temperature-rising.

- Long service life

The worm gearbox operates smoothly with low noise which is suitable for long-term contact work in harsh environments.

Applications

The NRV worm gearboxes are widely used in automation industry, industrial robots, aerospace, CNC machine tools, metallurgical mining, beer and beverage, tobacco light industry, environmental engineering, warehousing logistics, plastics machinery, lifting transport, three-dimensional parking, automobile manufacturing, textiles, food, ceramics and other fields.

Operating conditions

- The TQG NRV worm gearbox has good versatilitywhich is used with various mechanical equipment.

- Alarger transmission ratio could be achieved by a single-stage transmission. Most types of speed reducers have a good self-locking ability, and mechanical devices with braking requirements can save braking devices.

- The meshing friction loss of the worm screw teeth and the surface of worm gear toothis large, so that the transmission efficiency should be lower than that of the gear.

- The NRV worm gearbox has high requirements for lubrication and cooling.

Precautious

- Before use, please confirm that the turbine reducer and the mechanical safety supporting strength are within the safe range of the performance parameters of the reducer.

- The turbine gearbox has been filled with WA460 lubricant at the factory. After 400 hours of operation, the lubricant should be replaced. The oil change cycle is about 4000 hours later.

- The reducer casing body should retain enough lubricating oil, and regularly check the amount of oil.

- Avoid damage to the gearbox caused by sharp shaft damage caused by sharp equipment

- Check the direction of rotation before installing the machine.

- Set a safety cover, etc. in the rotation area.

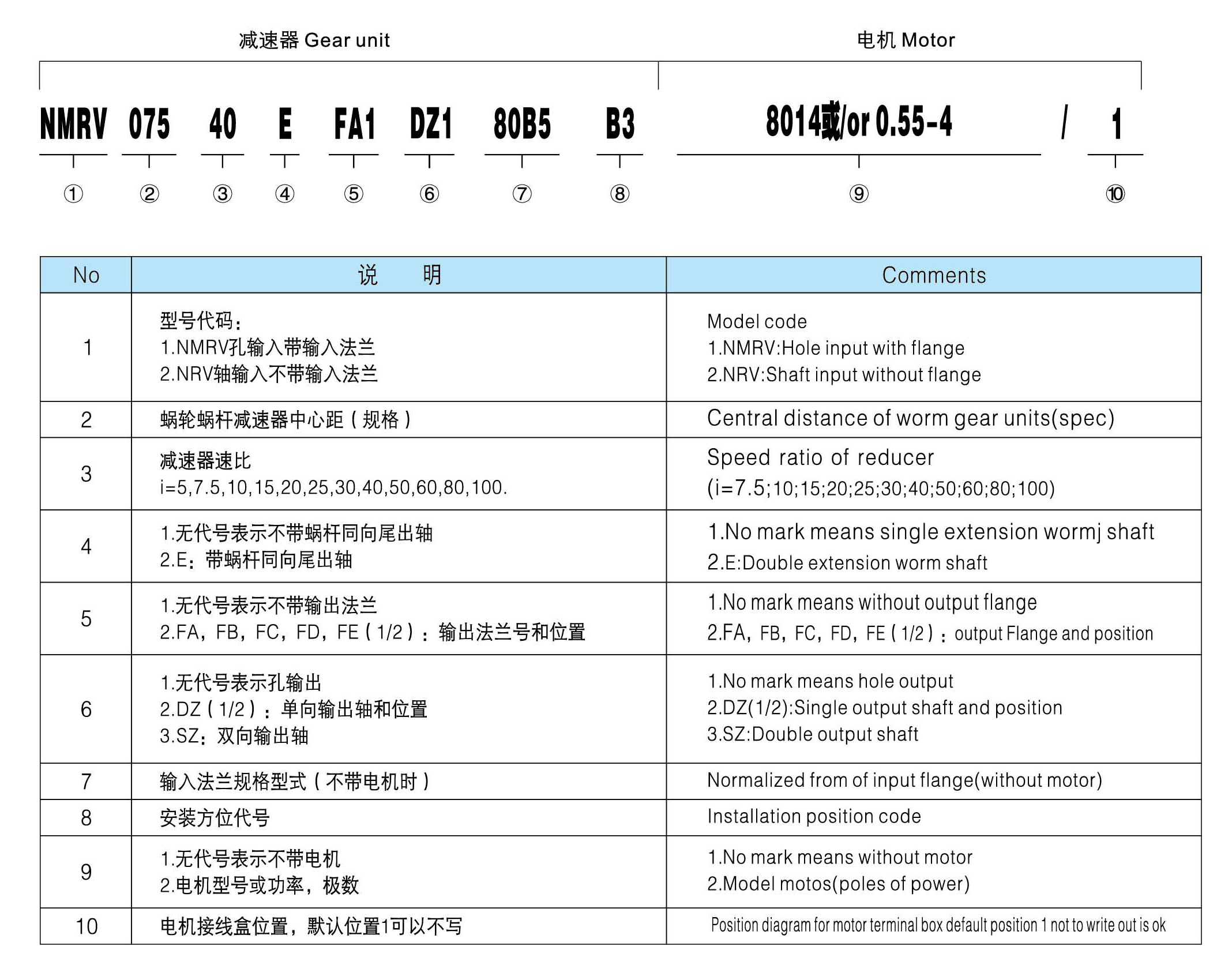

Indication of Model Numbers of NRV Worm Gearbox

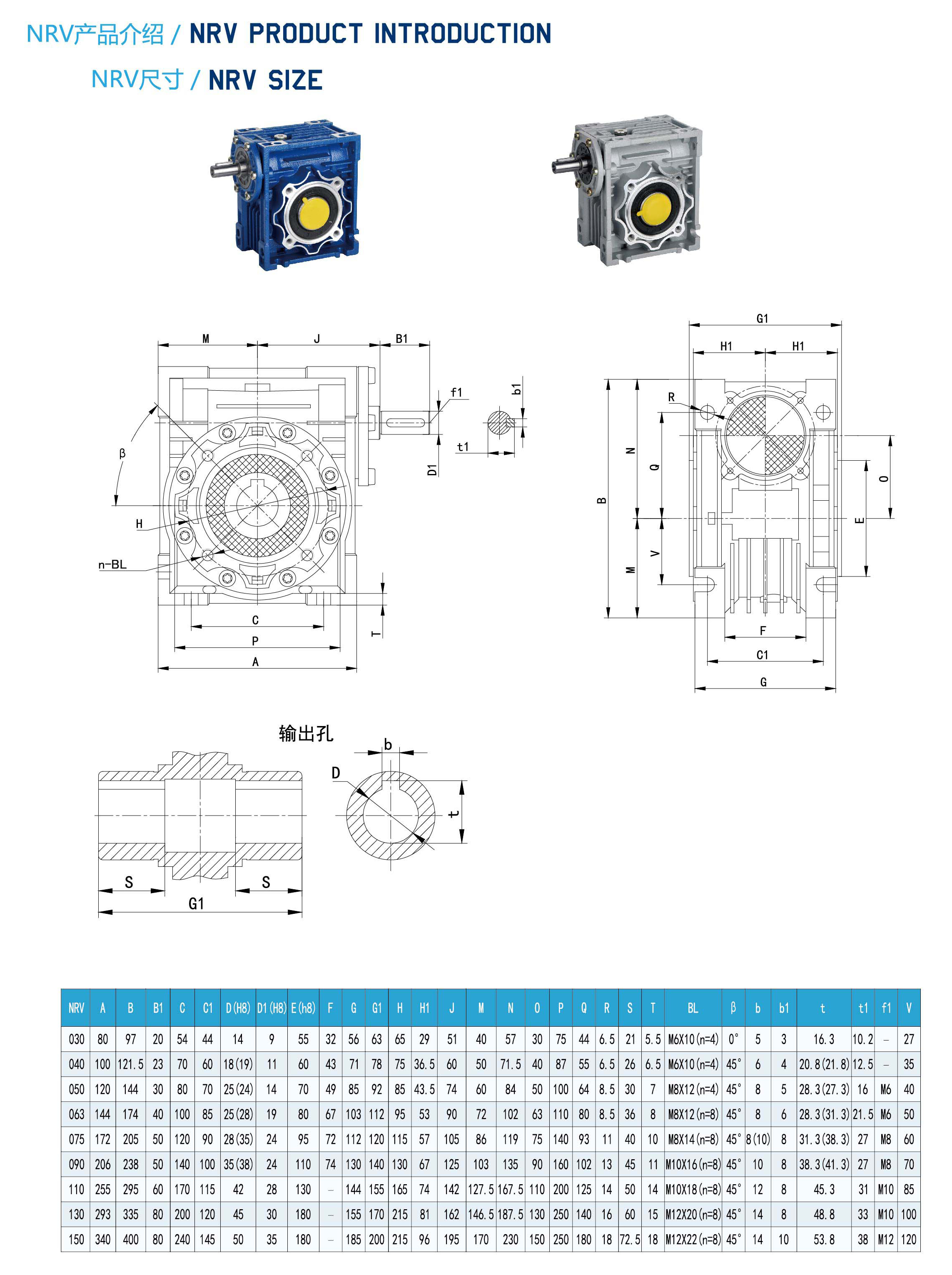

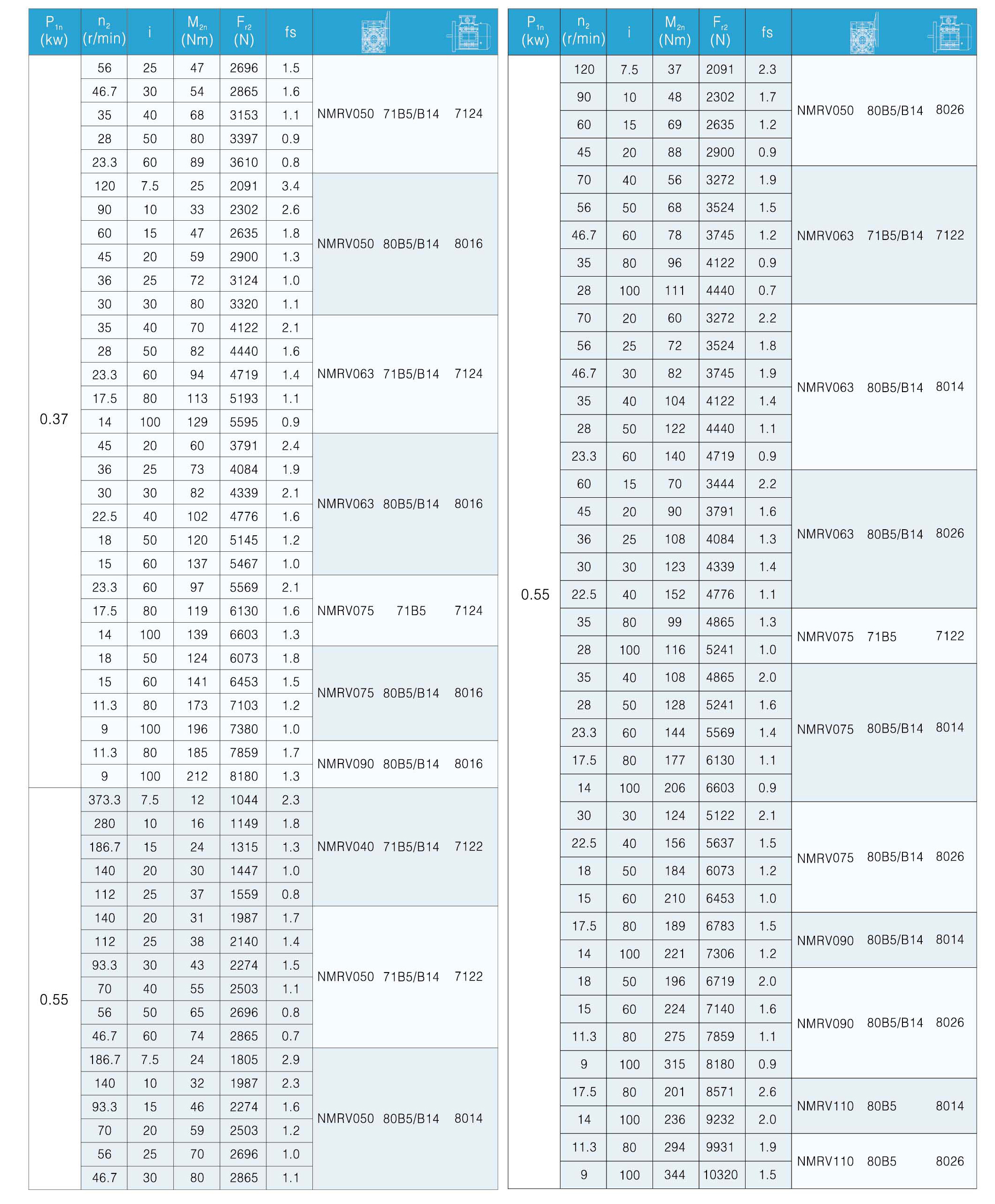

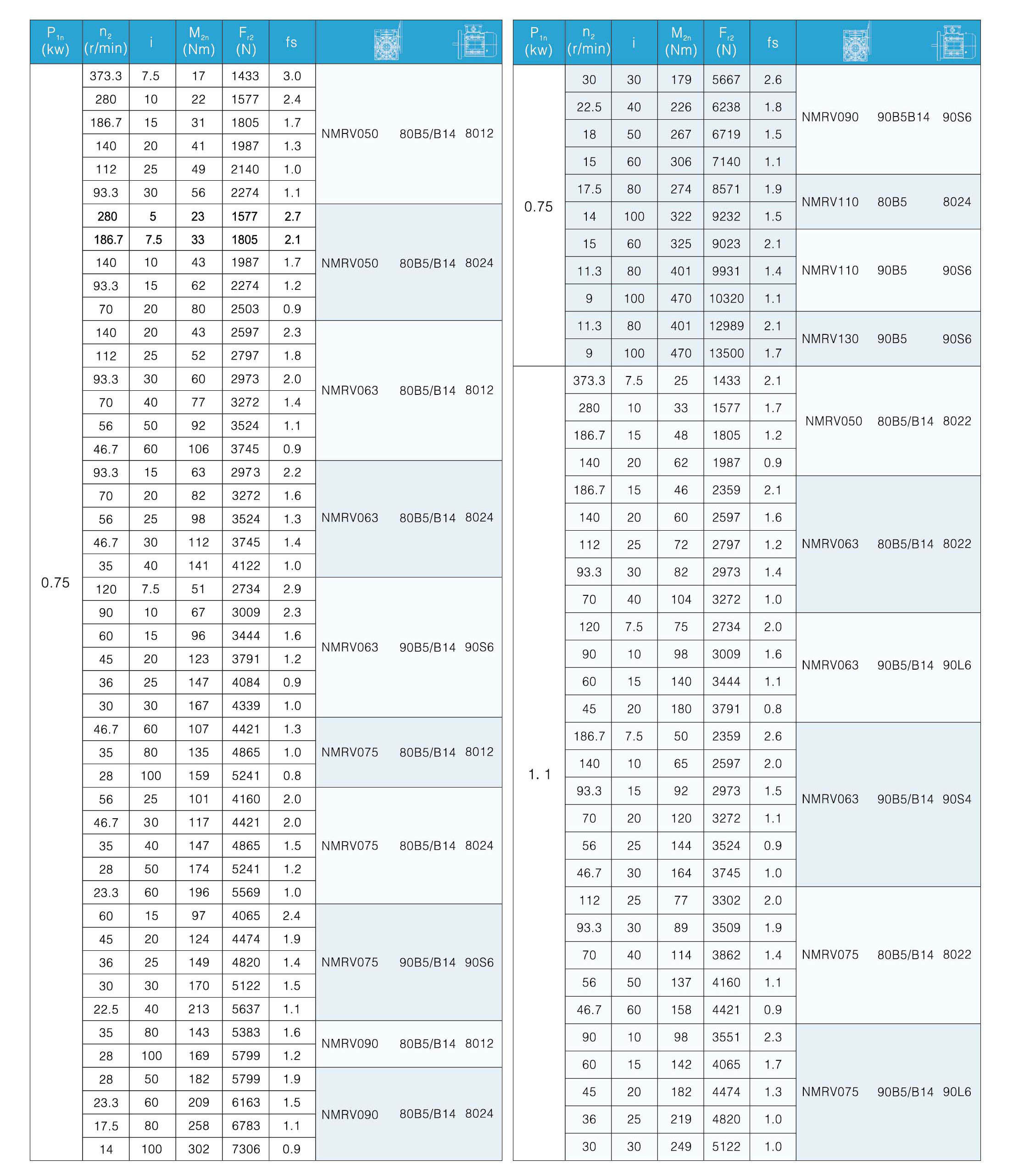

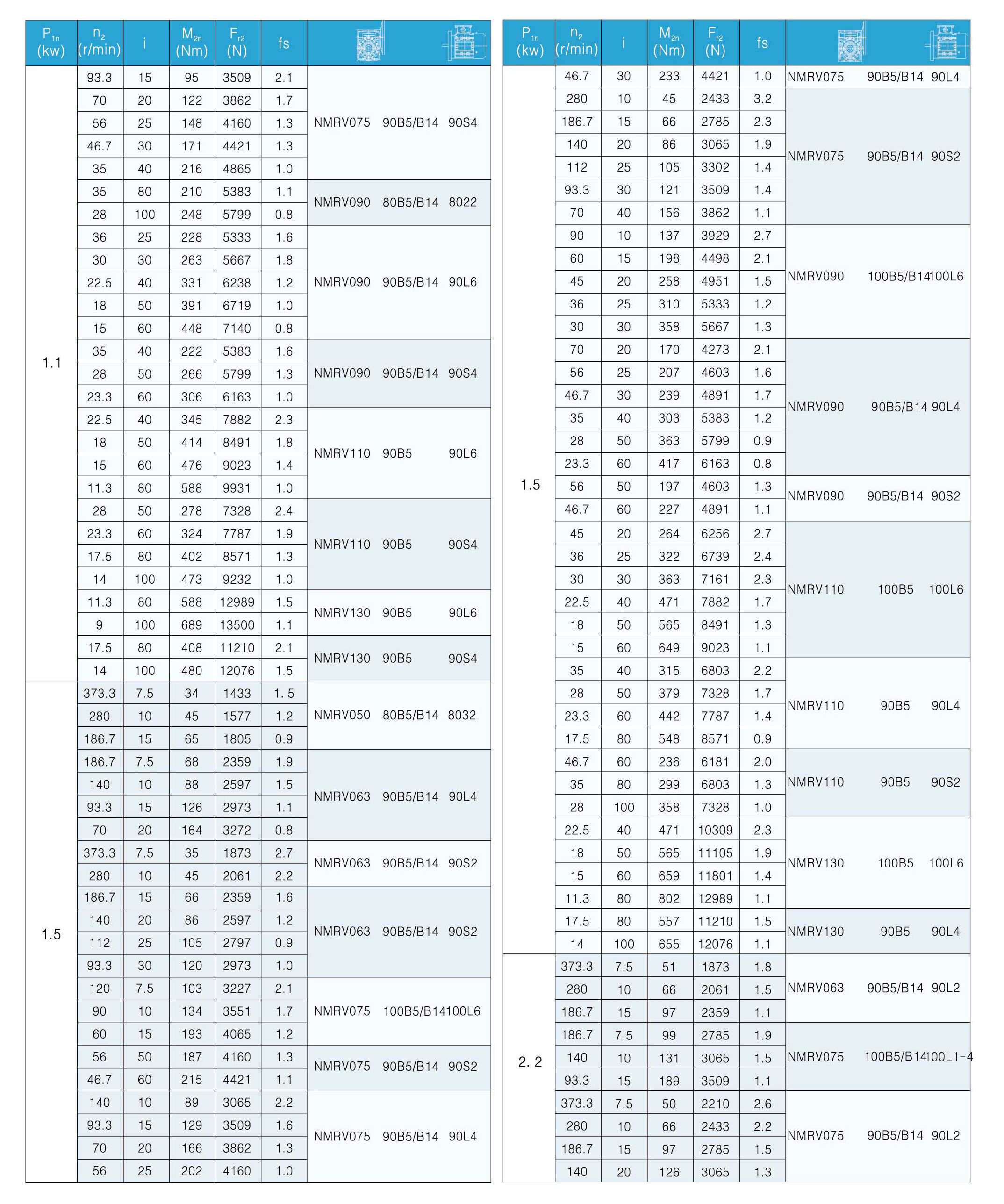

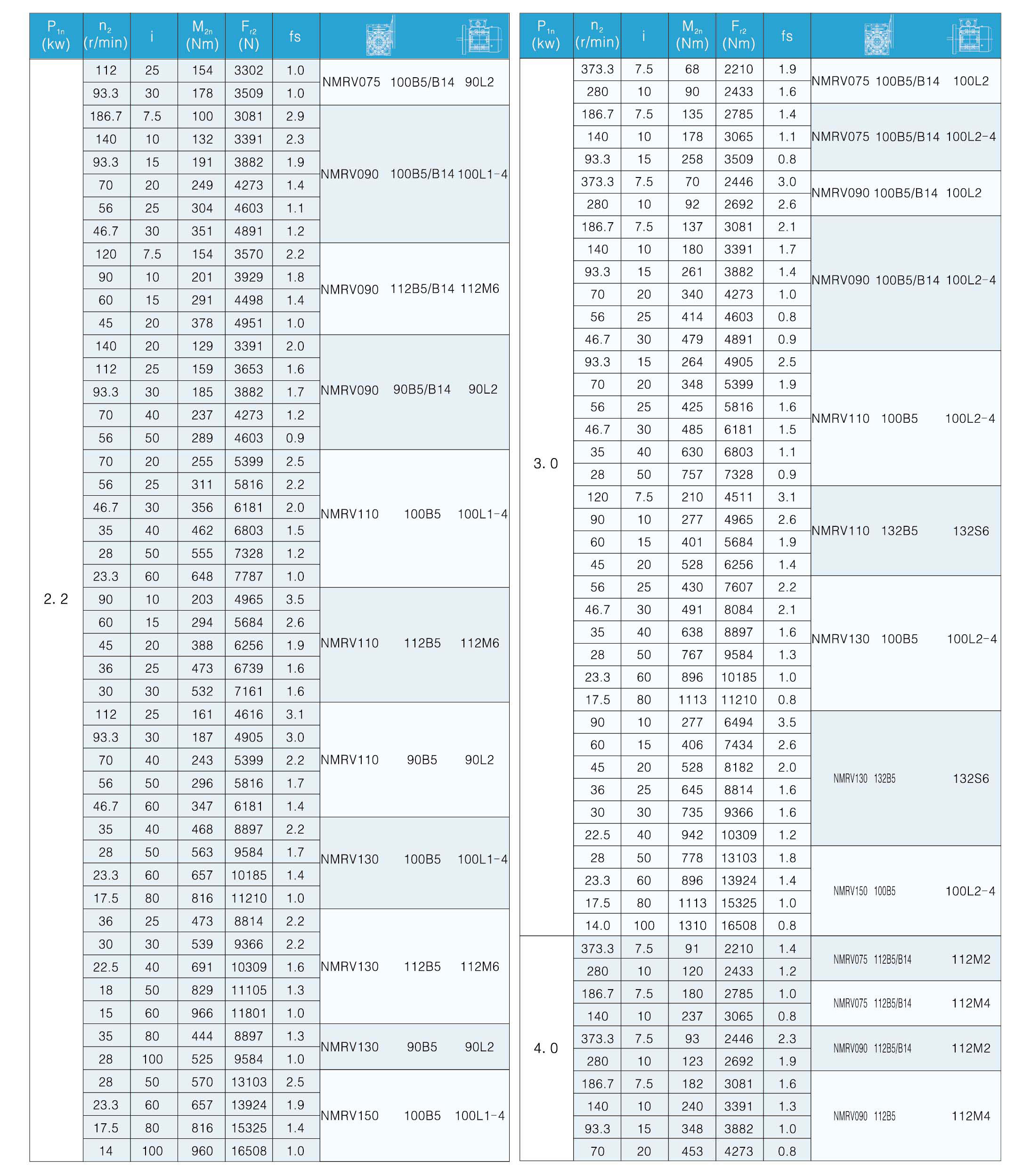

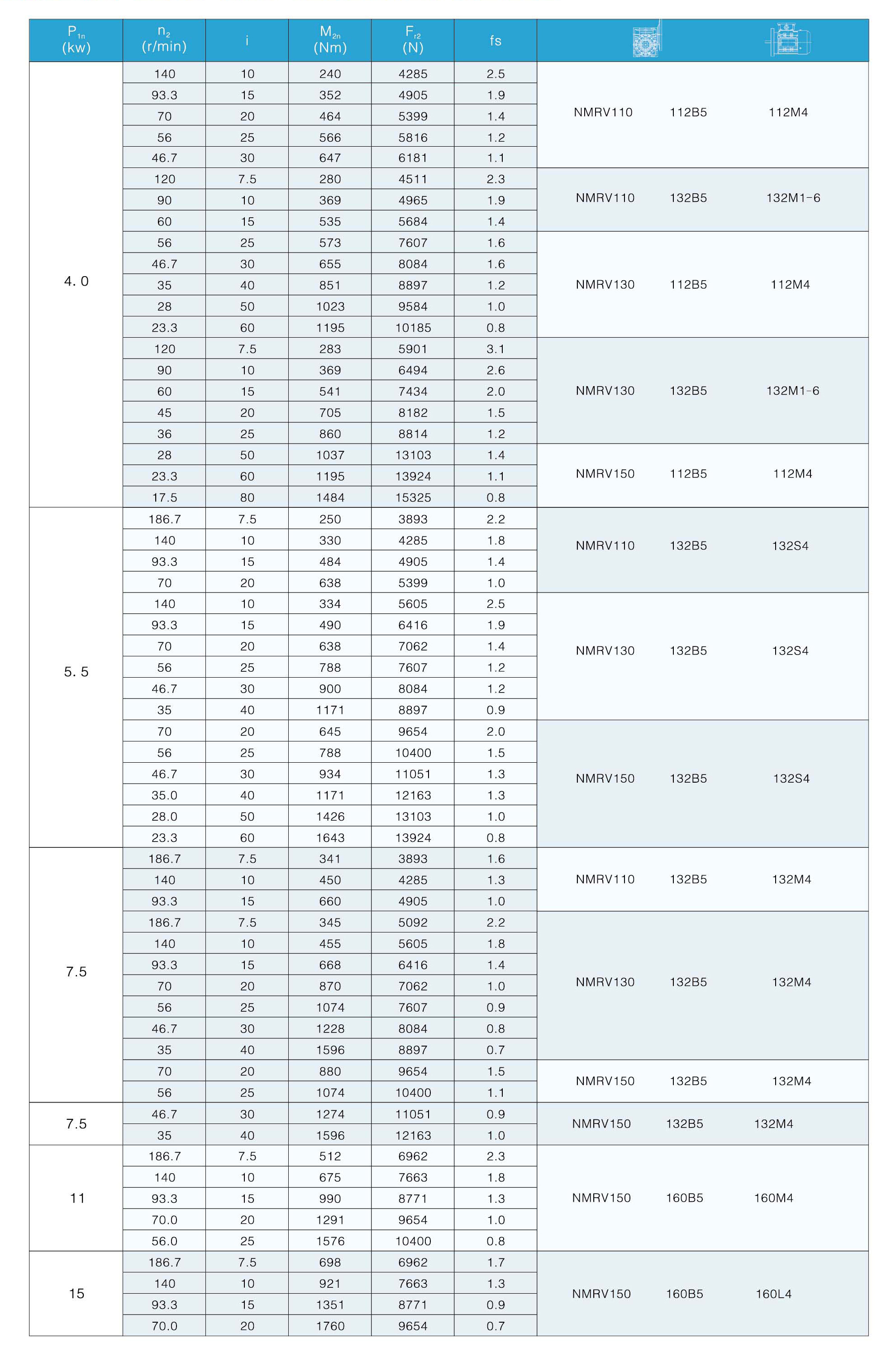

Specification Table of NRV Worm Gearbox

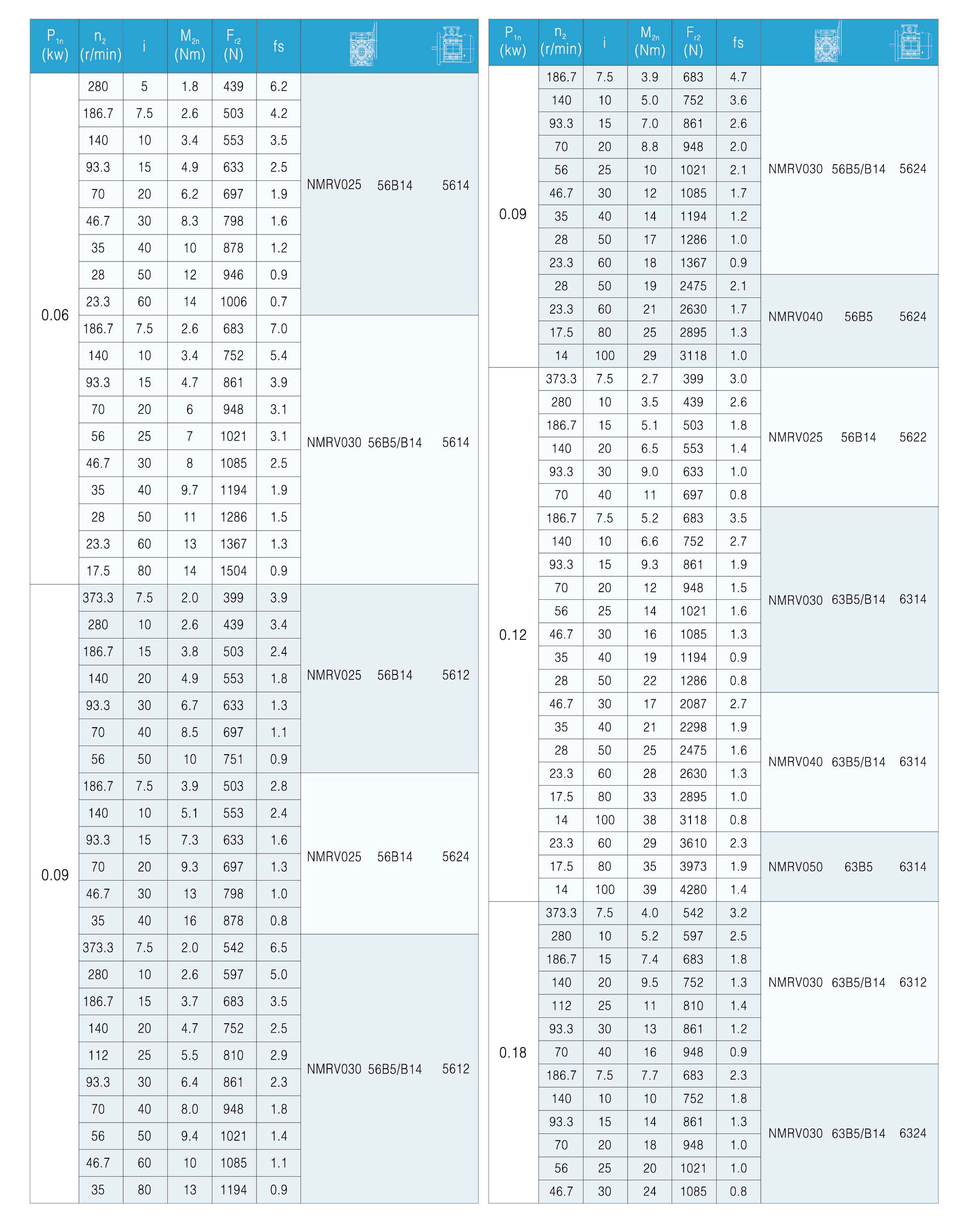

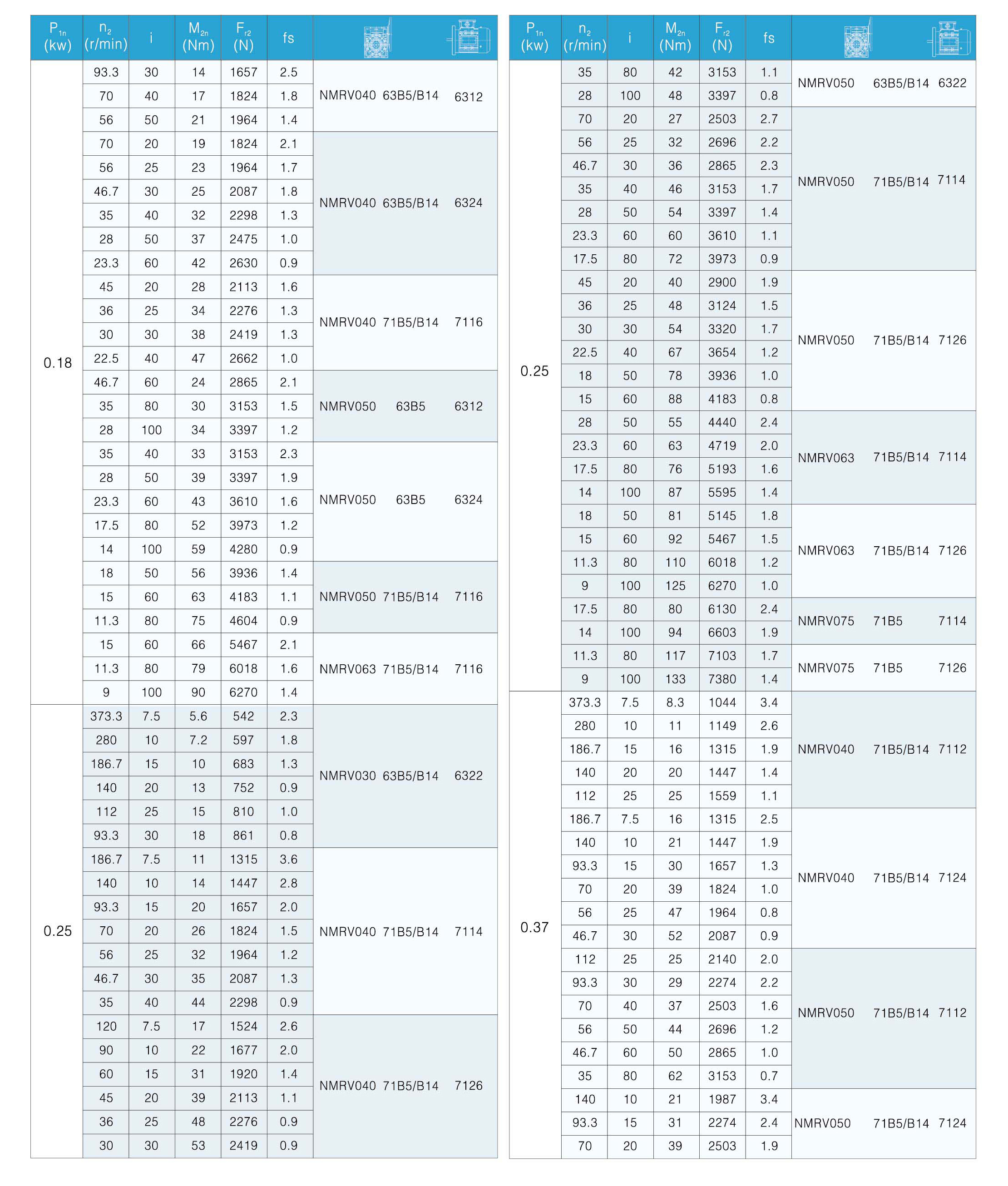

Catalogue of NRV Worm Gearbox

—Download the complete catalog in the top navigation bar